CLICK HERE FOR A FREE QUOTE

INSTALLATION is quick, clean and simple. Here's a step-by-step guide to the process:

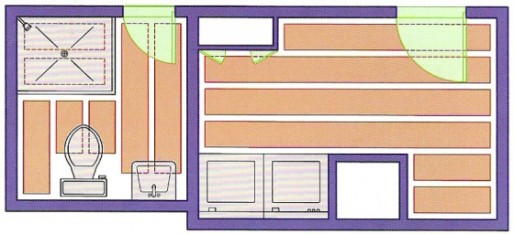

1. Plan |  |

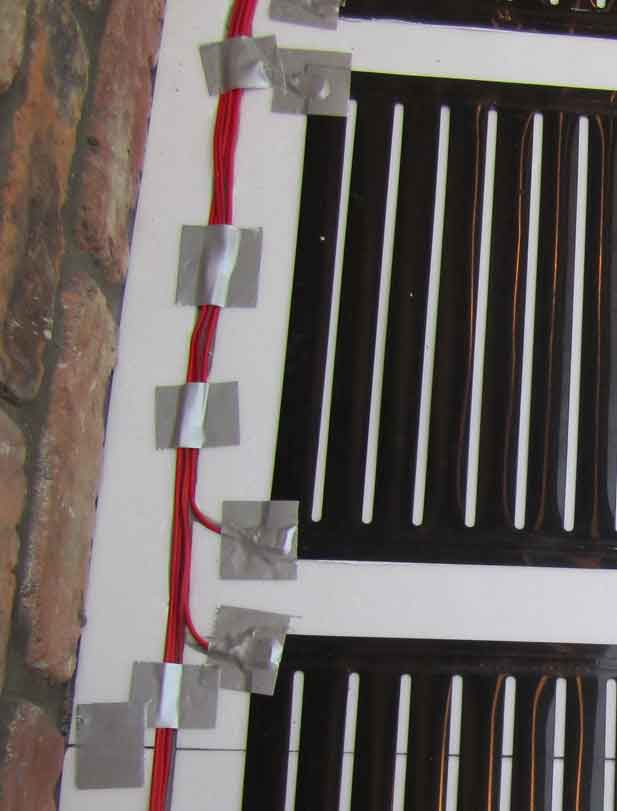

| 2. Install |

3. Connect |  |

4. Cover

Level the floor using proper mortar, underlayment or cement backer boards. Do NOT place a conductive material or non-recommended adhesive in direct contact with the heating elements.

To be efficient the heating elements have to be in direct contact with the finished flooring, with no air gaps. In bathrooms, showers, and wet areas, the heating elements should be installed under a waterproof membrane.

The heating elements provide a safe and even low temperature and can go under most floor coverings. Follow manufacturer's instructions.

GETTING IT RIGHT

Installation must conform to local building codes, regulations & trade practices.

he installation must be checked by a qualified electrician in accordance with current regulations BEFORE the element & wiring is covered.

All commercial, domestic and industrial wiring installations must be designed, constructed, inspected, tested and certificated to meet the requirements of BS 7671: 2008. )

A higher R-value is required under the heating elements as opposed to over with a ratio of 4:1.

Consult insulation manufacturer for deflection/load characteristics, and check that the product and installation procedure is approved for the application.

Any installation not done in accordance with manufacturer's instructions may invalidate the guarantee.

Our installation teams are all approved, fully-trained professionals. We have the experience to ensure that every job runs smoothly and to make sure that you are 100% satisfied with your EPWarmfloor system from the start.

GETTING IT RIGHT Our

installation teams are all approved, fully-trained professionals. We

have the experience to ensure that every job runs smoothly and to make

sure that you are 100% satisfied with your EPWarmfloor system from the

start.  |

|